DIY Hexagon Gazebo Collection

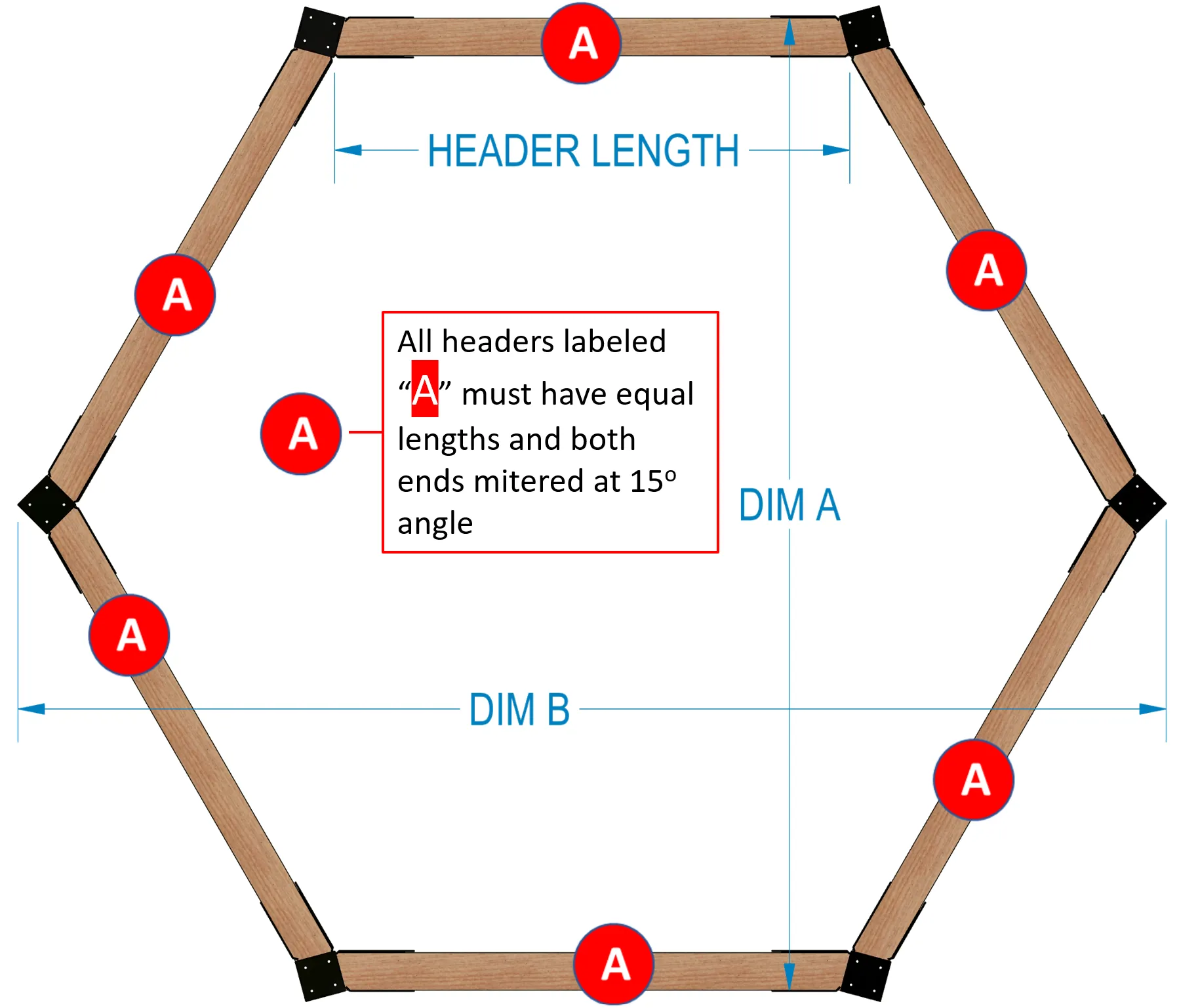

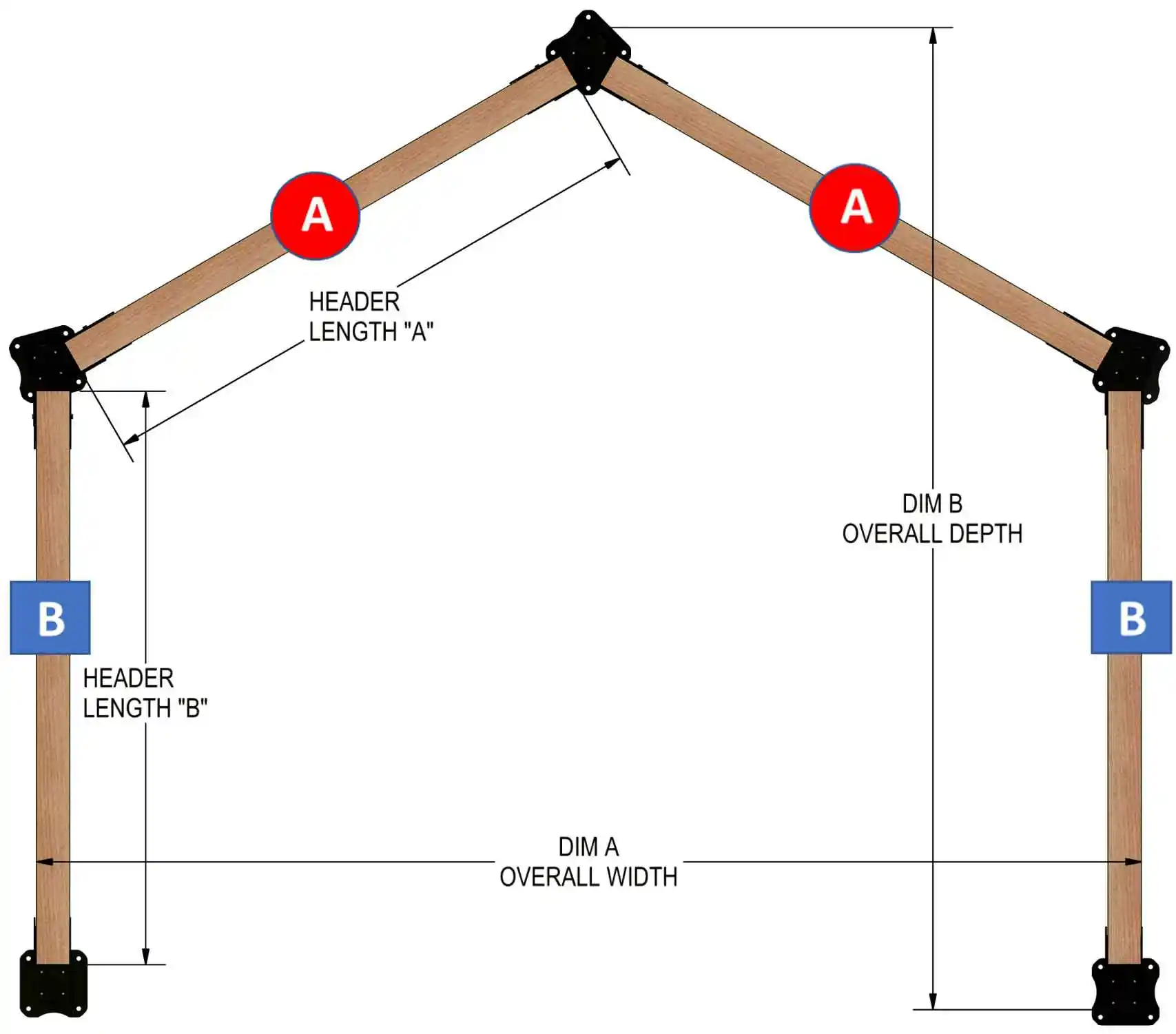

Find the perfect hexagon gazebo for your outdoor space. Bring elegance to your backyard with our Hexagon Gazebo Kits. These versatile kits include everything you need to create a charming outdoor retreat, except lumber & roofing materials. Crafted from high-quality materials, these gazebos are easy to assemble and add a stylish focal point to any outdoor space. Transform your garden into a cozy oasis with thiese unique and beautiful gazebos.

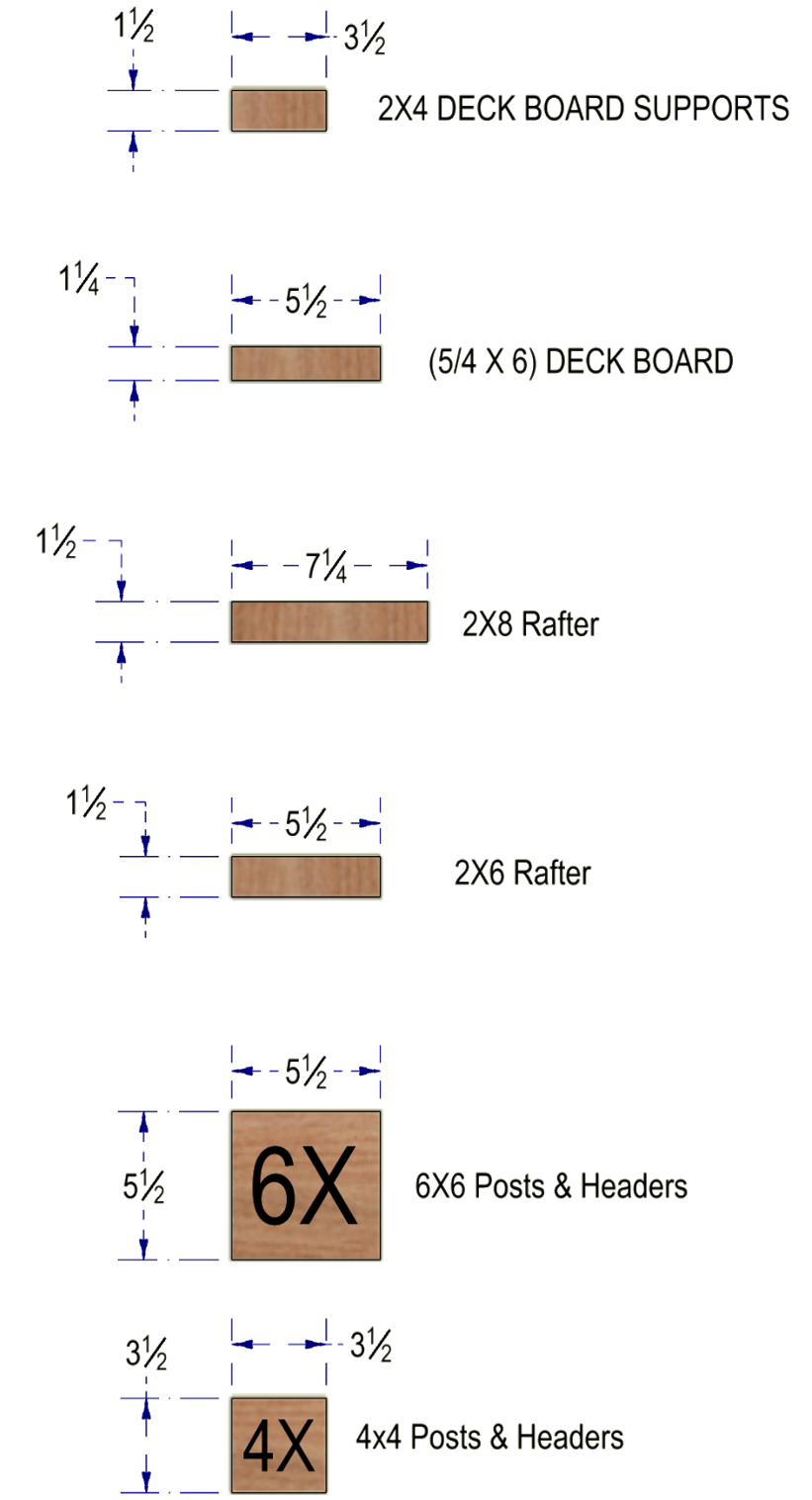

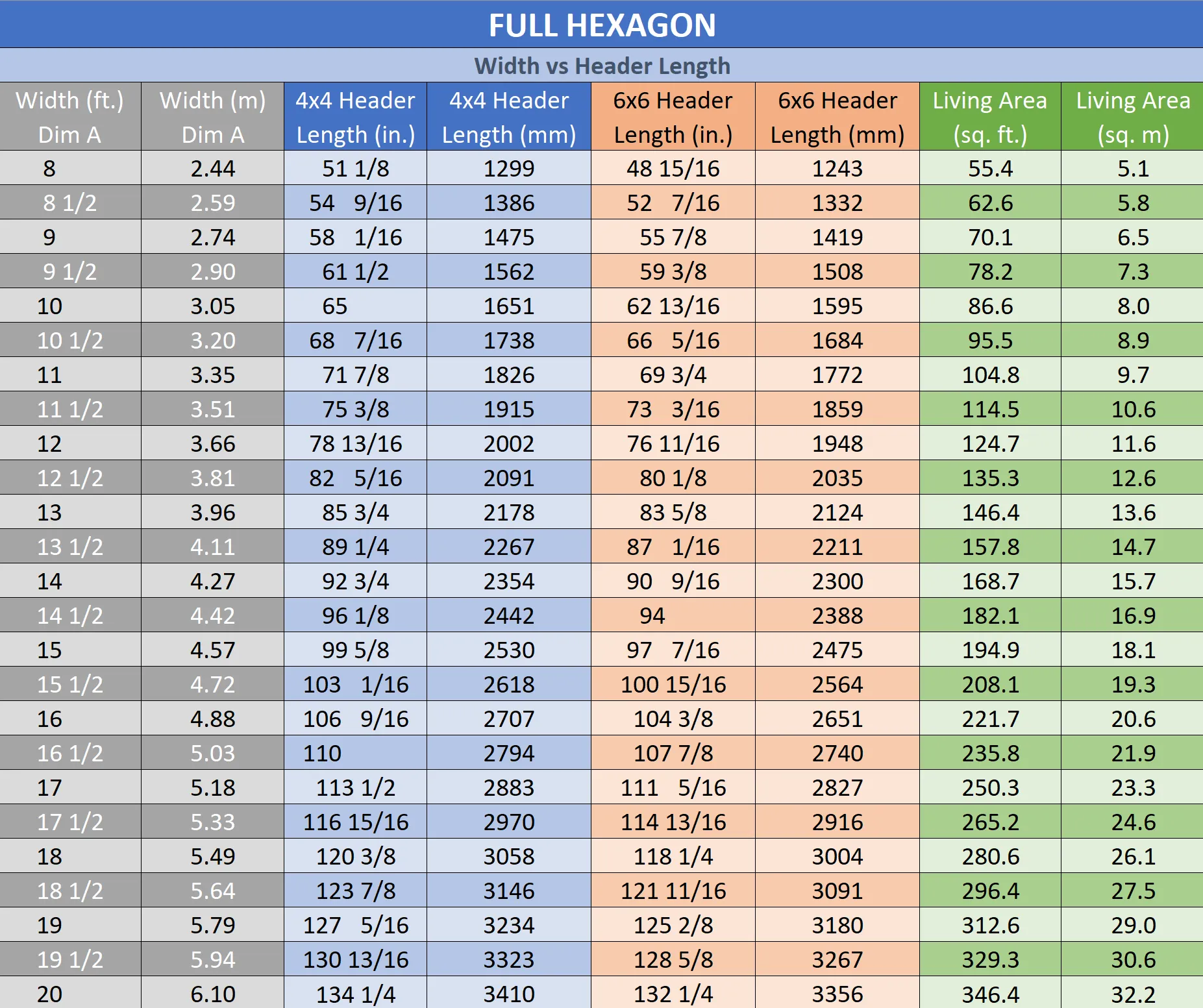

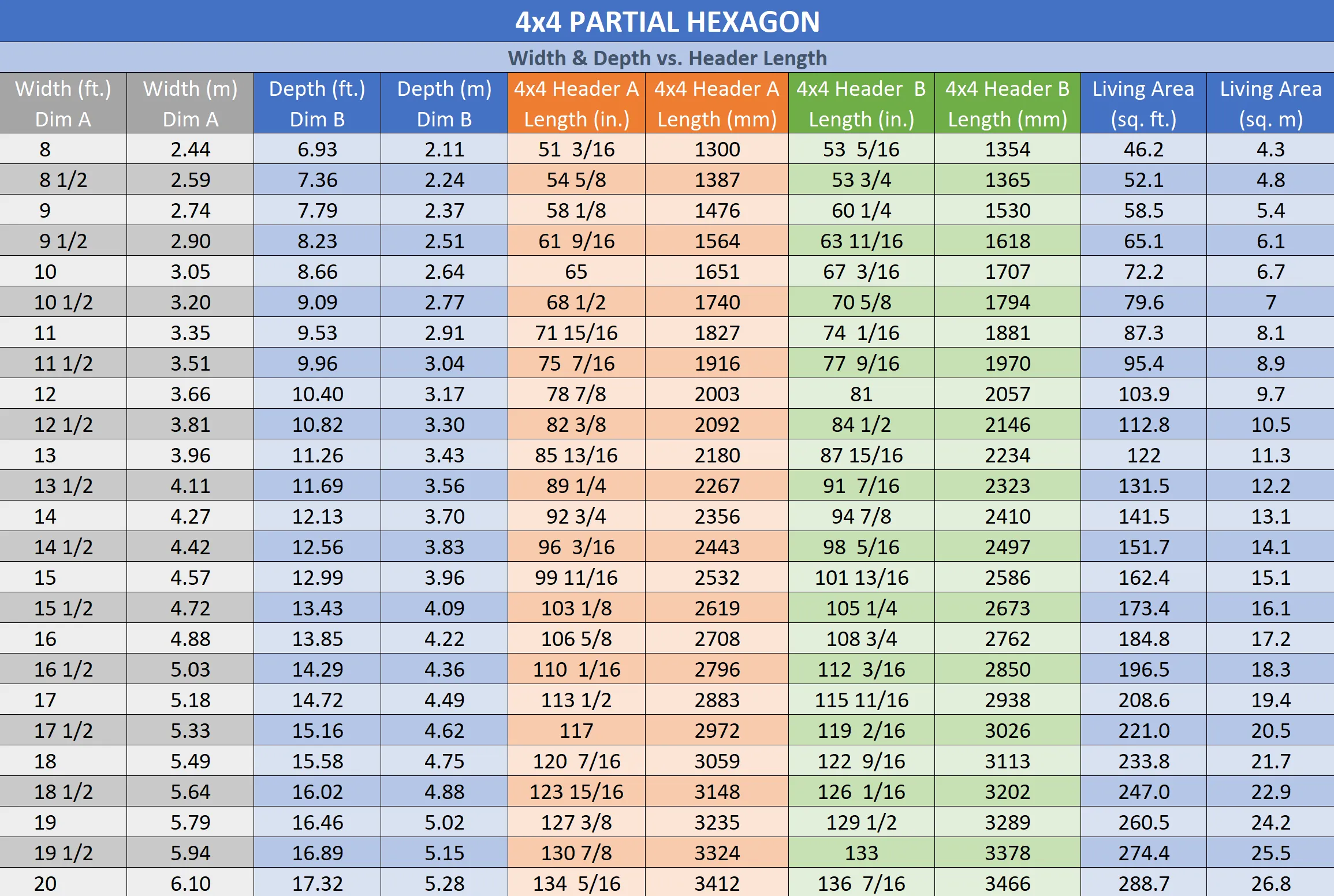

Perfect for relaxing or entertaining, this DIY project is sure to impress your friends and family. We offer Hexagon Gazebos in 4×4 and 6×6 lumber sizes. Explore our Hexagon Collection, floor anchor types, and the suitable shape to customize your own oasis.

Also explore our Hexagon Open Top Collection and our Octagon Collection.

Hexagon Solid Roof Series

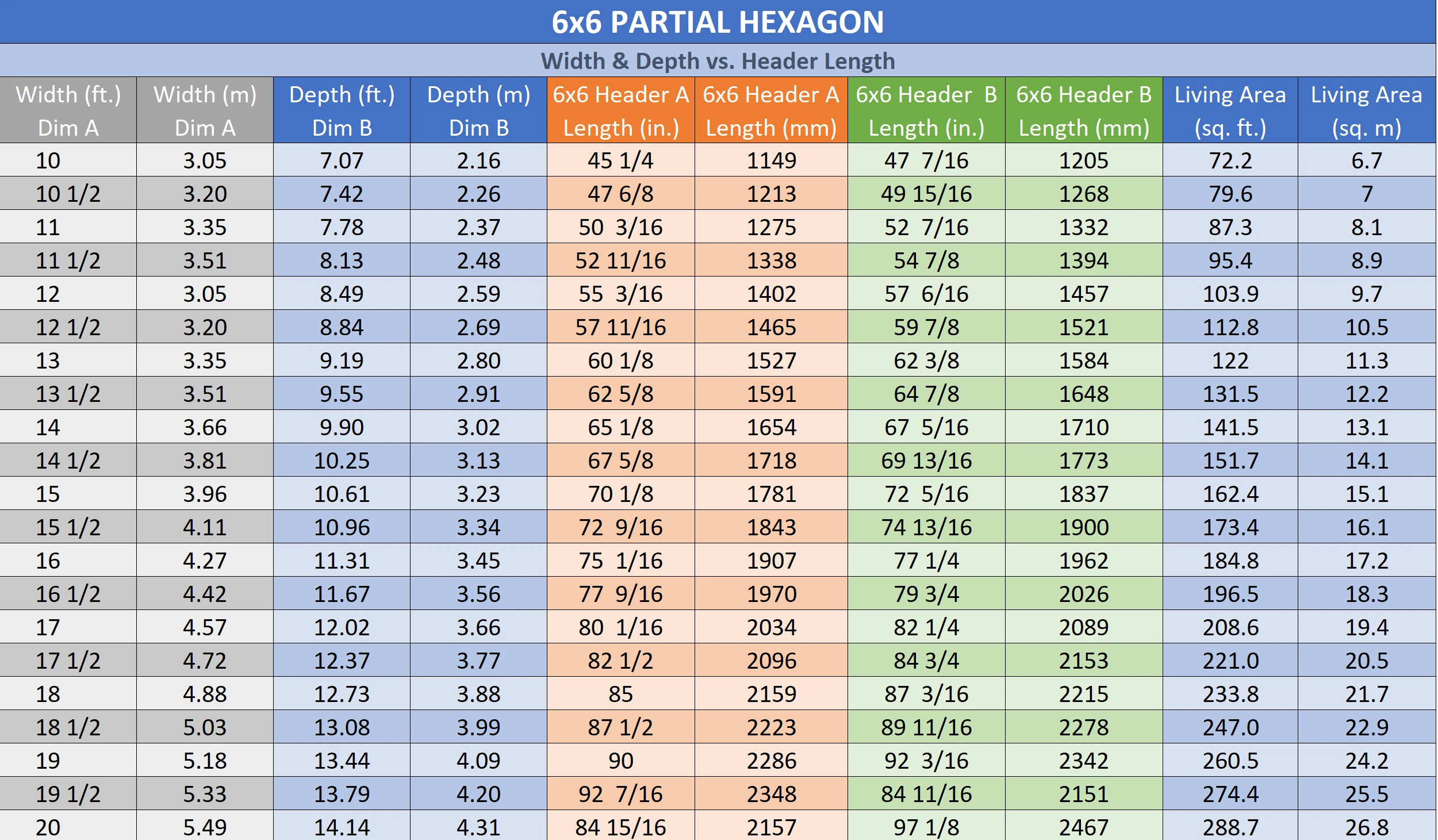

6x6 Lumber Size

6×6 sized Hexagon Gazebos are high-end structures.

They are super-sturdy and stiff and will provide a lifetime of outdoor relaxation and entertainment bliss.

4x4 Lumber Size

4×4 sized Hexagon Gazebos are easier to build and lower cost alternatives to the 6×6 sized hexagon gazebos.

While the 4×4 posts do flex slightly, they are structually sound and will provide a lifetime of outdoor relaxation and entertainment bliss.

You may also visit our Etsy Store and our Shopify store to browse through our products.

Contact Us

Our products are flexible and allow you to build any custom sized structure. We encourage you to custom size or custom-configure to suit your specific needs.

Contact Us if you have any questions, concerns, or custom configuration needs. We are here to serve you.