Modern Collection

Contact Us

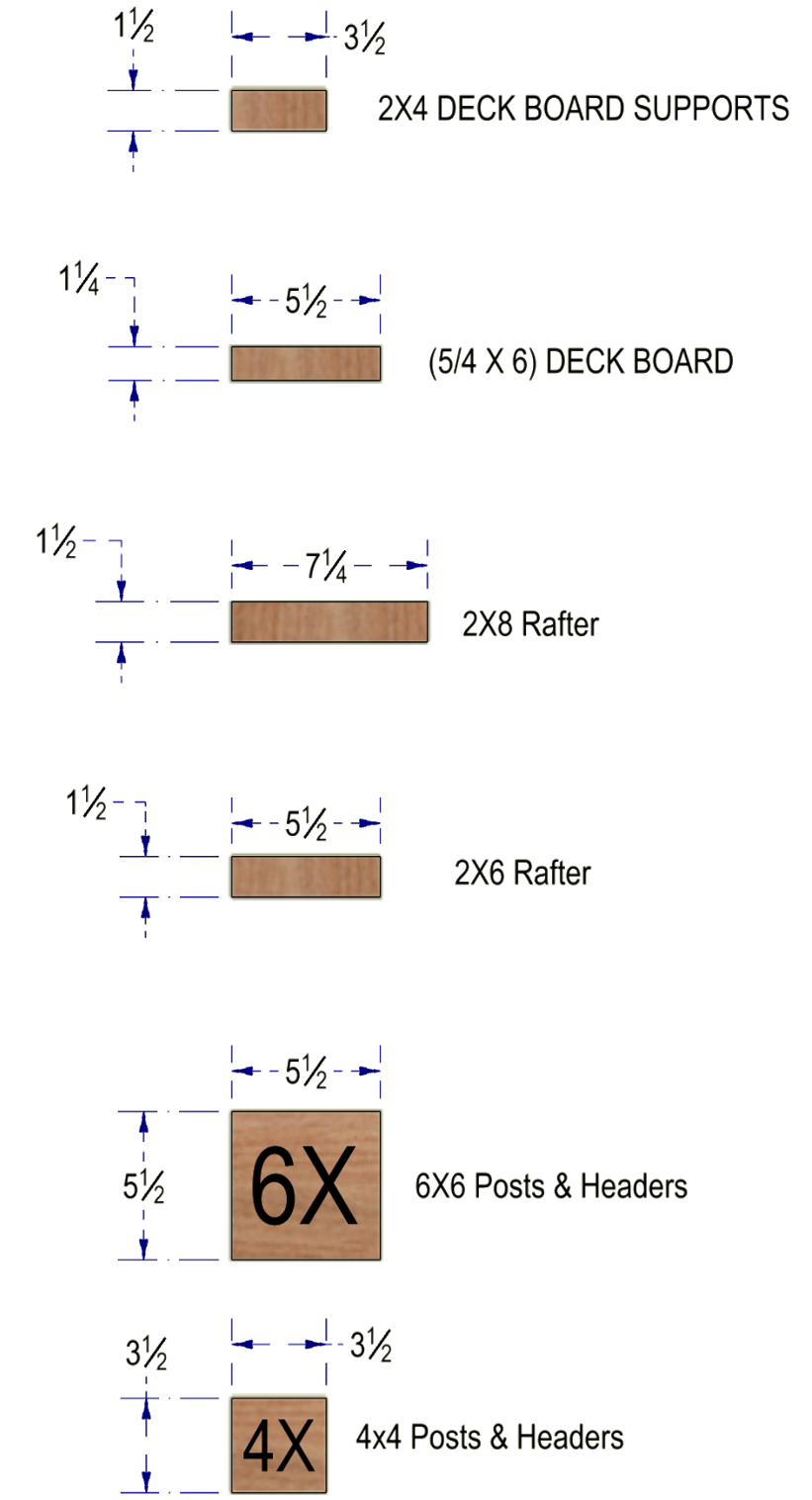

Our products are flexible and allow you to build any custom sized structure. We encourage you to custom size or custom-configure to suit your specific needs.

Contact Us if you have any questions, concerns, or custom configuration needs. We are here to serve you.