OCTAGON COLLECTION

Octagon Solid Roof Series

..Coming Soon

Contact Us

Our products are versatile and allow you to build any custom sized structure. We encourage you to custom size or custom configure our products to suit your specific needs.

Our products are versatile and allow you to build any custom sized structure. We encourage you to custom size or custom configure our products to suit your specific needs.

A racket & socket drivers are recommended to fully drive lag screws.

The 1/4″ x 1-1/4″ Lag Screws have a 7/16″ hex head. A 7/16″ Socket is required to drive the 7/16″ head lag screws.

The 3/8″ x 3″ Lag Screws used for raftered pergola brackets have a 3/8″ hex head. A 9/16″ Socket is required to drive the 3/8″ head lag screws.

1/2″ diameter x 2-3/4″ concrete bull anchor bolts are included with floor anchor brackets. These anchors are to be employed to secure floor anchor brackets to concrete pads and concrete footings.

Use the 1/2″ x 4″ masonry drill bit to drill 1/2″ x 2-1/4″ deep holes in concrete pads and concrete footings.

A 10″ compound miter saw is recommended for making straight, angled, and compound angled cuts as required. A 10″ sized saw will have the capability to cut compound angles in lumber members up to 2x8s.

Alternatively, a sliding compound miter saw can be used as a better alternative. Sliding compound miter saws have the capability to cut lumber members up to 2x12s and beyond.

We provide detailed information for you to plan your project. Use the information wisely and make wise judgements about the header lengths which directly drive the overall pergola size.

Example: if you decide to use 60” (1524 mm) length headers, instead of buying 96” (2438 mm) lumber and cutting off and discarding 36” (914 mm), you may be able to buy 120” (3048 mm) long 4x4s and yield two 60” (1524 mm) lengths. If you need a 72” long lumber member, you may be able to acquire an 84” long lumber and trim off only 12”. Check with local lumber yards for available lengths of lumber and plan accordingly.

Lumber Size Requirements are as provided, below:

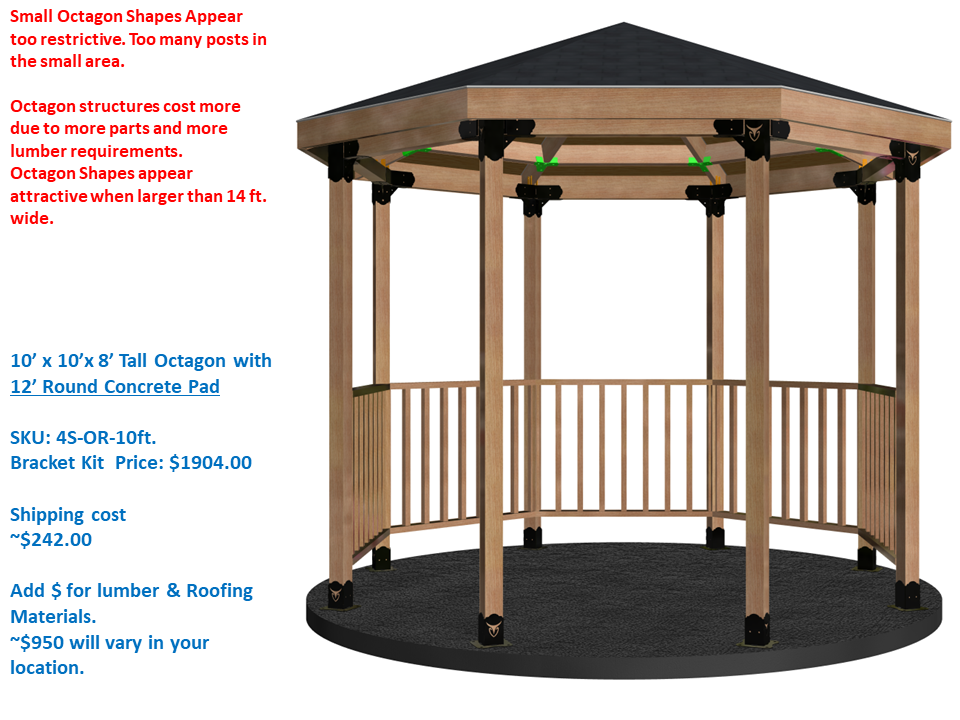

We have designed our products to allow creation of unlimited sizes of Octagon shapes in widths ranging between 8 ft (2,438 mm.) and 20 ft (6,096 mm.). Although an Octagon shape as small as 8 ft wide is possible, we do not recommend Octagons in sizes smaller than 12 feet. This because Octagon Shapes do not appear attractive when too small. There will be too many vertical posts in close proximity and hinder your movement in and out easily.

Instead, for sizes smaller than 12 feet, consider our Hexagon shaped products. Hexagon shapes appear cosmetically attractive in small sizes. See this link for our Hexagon Collection offerings: https://riooutdoors.com/hexagon-solid-roof-collection/

If available space allows, consider a minimum Octagon width of 12 feet. Larger Octagons are cosmetically attractive.

The size of octagons are defined by DIM A (width) and DIM B (depth). As the Header Length A increases, the width of the Octagon, DIM A, increases, accordingly. The steel brackets remain unchanged, only the header lengths increase as the octagon width increases.

As long as you adhere to common building practices and building structural strength requirements for open horizontal spans as allowed by your local building codes, you can vary the size of your custom structure as you wish. Just remember to limit the span of the lumber members within limits specified by your local building codes. This is especially important for the roof rafter member size and cross-tie member size in areas where snowload is a concern.

Just remember that our brackets make the lumber joints “super strong”. But the lumber, itself, is the structural item that limits the open spans.

The size of the octagon shape is determined by the overall width of the octagon shape. The size of the octagon shape you can create using our brackets ranges between 10 ft (3,05 m) and 20 ft (6.1 m).

[Larger sizes than 20 ft (6.1 m) are available with special consideration. Please contact us directly for special requirements for larger sizes than specified here.]

The Header Length A is the primary driving factor which determines the octagon dimensions.

Note that DIM A and DIM B are equal and are measured between two parallel sides of the octagon.

DIM A defines the width of the octagon. Refer to Table 1, below.

If you desire a 12 ft. (3.66 m) wide octagon, select the row in column [Width (ft.) DIM A] that contains the dimension 12 ft. (3.66 m).

The header length in the same row equals 56 11/16” (1440 mm) for 4×4 size and 55 3/16″ (1402 mm) for 6×6 size.

You will cut and prepare eight headers, all with their lengths equal to this header length (either 4×4 or 6×6 specific).

See header A preparation details here.

The lengths of headers, marked A and B ,determine the width and depth of partial octagons.

Length of header A determines width dimension (DIM A) of the partial octagon.

A combination of lengths of headers A and B define the depth dimension (DIM B) of the partial octagon.

Refer to Tables 2 and 3, below.

Headers marked A and B can have almost equal lengths, with variance in length only due to the cut angle difference on one end of Header B. Tables 2 and 3, below, assume that the lengths of headers marked A and B are almost equal.

See header A preparation details here.

See header B preparation details here.

Surface Mount Anchor type

Floating Deck Anchor type

Full Octagon and Partial Octagon structures are available in freestanding configuration. Freestanding structures are available in surface mounted and floating deck anchor types.

All Freestanding structures are available as lattice topped structures or as solid roofed structures.

Partial Octagon structures are available in freestanding configurations and wall attached configurations. Both freestanding and wall attached configurations are available with surface mounted and floating deck anchor types.

Both Freestanding and Wall Attached structures are available as lattice topped or solid roofed structures.